◎The machine uses advanced electronic digital control system. Yarn package forming, yarn twist and yarn tension will be set on the display. Take-up and traverse motion are independently driven by servo motor. Easy operation and powerful functions.

◎Synchronization protection function for interruption of power supply and PL C guides three separate motors to run at an invariable speed ratio so as to ensure same yarn twist during starting and stop machine.

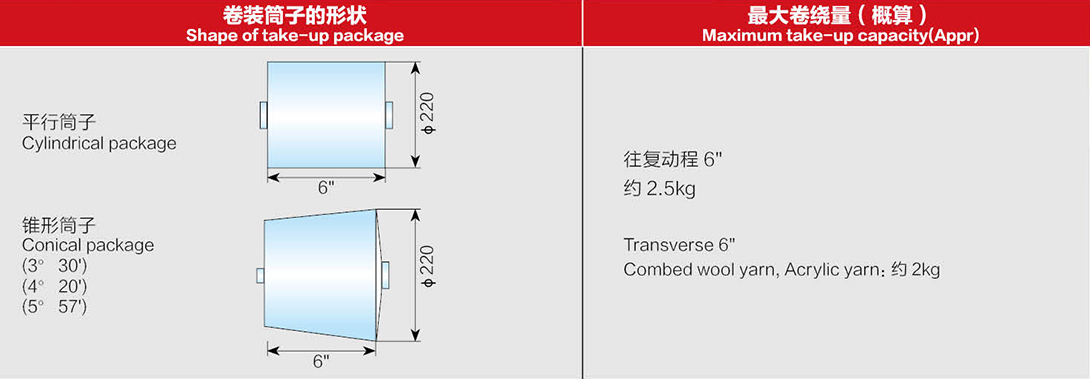

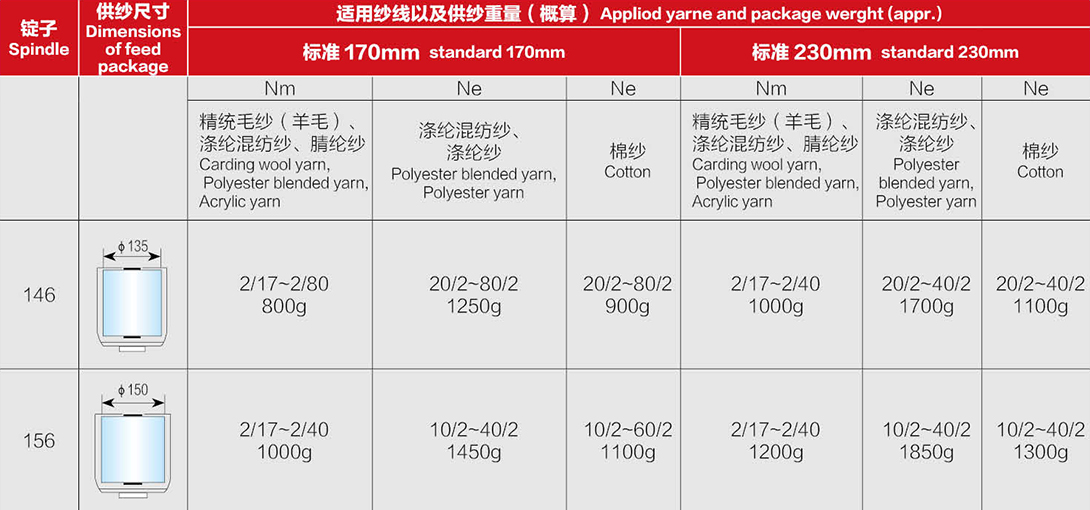

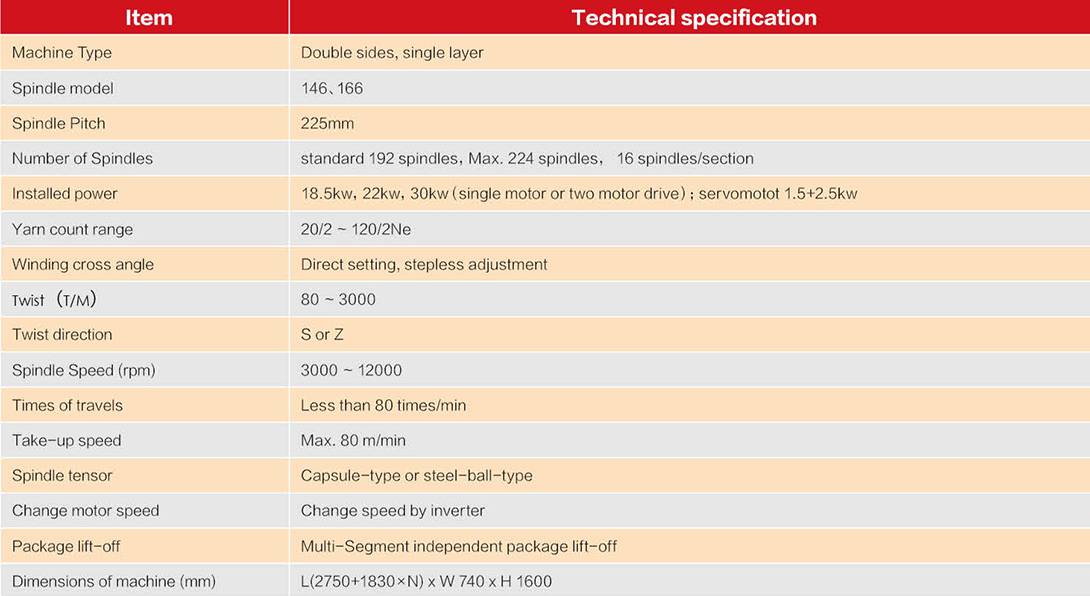

◎Compact structure design, small occupying space, different spindle specifications for choice.

◎Take-up tension can be adjusted at will, so the soft dye package can be directly produced.

◎High steady spindle speed, gentle locating of spindle pot, lower vibration, load supporting structure of bearing-end on spindle blade and lower maintenance thanks to high quality spindle with perfect structure.

◎Lower installation position of spindle, longer efficient twist area and smaller yarn balloon ensure lower twisting tension, even twist and lower strength reduction of yarn.

◎When braking spindle, the spindle is completely detached with tangential belt, thereby ensure a long life of them.

◎Package lift-off mechanism can avoid the abrasion of yarns so as to supply perfect package for next process.

◎Optional accessories: balloon limiter, air splicer, traveling cleaner, reserve tail mechanism, waxing device, cradle damping device.

0575-86288859

Zhejiang Taitan Co. Ltd

Zhejiang Taitan Co. Ltd  Email

Email

浙公网安备 33062402000018号